|

|

Glen Frazer Free-mo Module - Restoration

After 15 years of transport, set-up, and tear-down, the module's track developed a

"roller coaster" profile. This caused trains to spontaneously break in two (uncouple) as the

cars' couplers moved vertically through the hills and dales. Consequently, in 2015 Glen Frazer

was taken out of service while the root cause of this issue was studied and solutions explored.

Apparently, over time the Liquid Nails latex glue used to attach the foam tops to the wooden

frames became brittle, and the foam tops shrunk and warped (possibly due to slow outgassing

of the foam material). These two factors caused the foam tops to pull away from the wooden

frames, resulting in a small hill at the center of each section and dips at the section joints.

To get Glen Frazer operational again, restoration began in late 2018 and extended well

into 2019. On the Derail, Loading Ramp, and West Switch sections, the foam tops were

stabilized relative to the wooden frames, the main track was replaced, and the worst dip on

the siding track was repaired. Also, all the MSS hardware was upgraded to V2.0 compliance,

the end pigtail connectors were updated to PowerPoles to comply with current Free-mo

standards, and the LocoNet throttle bus and panels were completely replaced.

After 15 years of transport, set-up, and tear-down, the module's track developed a

"roller coaster" profile. This caused trains to spontaneously break in two (uncouple) as the

cars' couplers moved vertically through the hills and dales. Consequently, in 2015 Glen Frazer

was taken out of service while the root cause of this issue was studied and solutions explored.

Apparently, over time the Liquid Nails latex glue used to attach the foam tops to the wooden

frames became brittle, and the foam tops shrunk and warped (possibly due to slow outgassing

of the foam material). These two factors caused the foam tops to pull away from the wooden

frames, resulting in a small hill at the center of each section and dips at the section joints.

To get Glen Frazer operational again, restoration began in late 2018 and extended well

into 2019. On the Derail, Loading Ramp, and West Switch sections, the foam tops were

stabilized relative to the wooden frames, the main track was replaced, and the worst dip on

the siding track was repaired. Also, all the MSS hardware was upgraded to V2.0 compliance,

the end pigtail connectors were updated to PowerPoles to comply with current Free-mo

standards, and the LocoNet throttle bus and panels were completely replaced.

Below: The Derail section with about half the pink foam

blocks in place. This section could be on its side while the

foam blocks were installed because the foam top had been

re-glued to the frame during the failed 2015 ad-hoc repair.

blocks in place. This section could be on its side while the

foam blocks were installed because the foam top had been

re-glued to the frame during the failed 2015 ad-hoc repair.

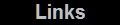

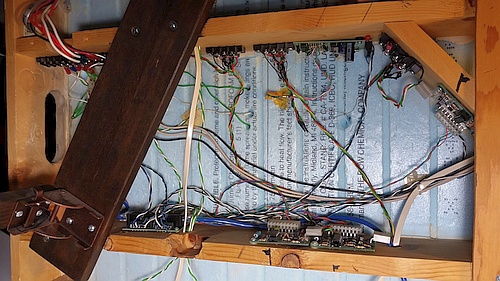

Below: The old MSS hardware consisted of

individual boards for each function with a

rat's nest of wiring interconnecting it all.

individual boards for each function with a

rat's nest of wiring interconnecting it all.

Below: Great risk results in great reward - hopefully. The

styrene shims were Gorilla-glued in place and a heavy

vise used as weight to keep everything flat as things cured.

styrene shims were Gorilla-glued in place and a heavy

vise used as weight to keep everything flat as things cured.

Below: The completed shims under the siding track, background.

At center, the cork under the main track had to be removed and

repaired - the track had been soldered to PCB tie plates at the

section joints, and they did not come out cleanly.

At center, the cork under the main track had to be removed and

repaired - the track had been soldered to PCB tie plates at the

section joints, and they did not come out cleanly.

Below: The replacement cork at the Derail/Ramp section

joint is curing with heavy weight holding it in place.

joint is curing with heavy weight holding it in place.

Below: The new cork at the Ramp/West Switch section

joint. Tape was used to mark where power feeds come

up through the trackbed - the wires were re-soldered to

the new track when it was installed later.

joint. Tape was used to mark where power feeds come

up through the trackbed - the wires were re-soldered to

the new track when it was installed later.

Below: The flex track was pre-formed to match the centerline

curves. Intermediate rail joints were soldered to create lengths of

contiguous track to cover each section. The power feed wires

were soldered to the rail undersides (green and white wires). With

the assembled track raised on foam blocks, latex Liquid Nails glue

was spread thinly on the cork. The track was then pressed into the

glue, carefully aligning it on the centerlines. As the glue slowly

cured, rail spikes were installed as needed to hold the track in

place, and bubble levels were used to ensure side-to-side level.

contiguous track to cover each section. The power feed wires

were soldered to the rail undersides (green and white wires). With

the assembled track raised on foam blocks, latex Liquid Nails glue

was spread thinly on the cork. The track was then pressed into the

glue, carefully aligning it on the centerlines. As the glue slowly

cured, rail spikes were installed as needed to hold the track in

place, and bubble levels were used to ensure side-to-side level.

Below: Track centerlines, including easement curves, were

marked on the repaired cork roadbed using black Sharpie

pens. Before installing the new Walthers/Shinohara code 83

track, printed-circuit-board (PCB) tie plates were glued in

place at the section joints. These have copper pads to which

the rails are soldered - this reinforces the rail attachment to

prevent accidental track damage during module handling.

The last 1/4" of rail was left loose - at setup time, a "floating"

rail joiner is slid across the joint to ensure rail alignment.

marked on the repaired cork roadbed using black Sharpie

pens. Before installing the new Walthers/Shinohara code 83

track, printed-circuit-board (PCB) tie plates were glued in

place at the section joints. These have copper pads to which

the rails are soldered - this reinforces the rail attachment to

prevent accidental track damage during module handling.

The last 1/4" of rail was left loose - at setup time, a "floating"

rail joiner is slid across the joint to ensure rail alignment.

Below and Right: On the East Switch section, the most offensive track

issue was a significant "roll-off" (drop) at the Free-mo endplate. I used

a hacksaw blade to undercut the existing PCB tie plate, and made a

styrene wedge to raise the track end.

issue was a significant "roll-off" (drop) at the Free-mo endplate. I used

a hacksaw blade to undercut the existing PCB tie plate, and made a

styrene wedge to raise the track end.

With the track now repaired and the electricals back in place, Glen Frazer was successfully tested in mid-2019 in a Free-mo layout

in Bakersfield, CA. Just one minor wiring error was found and corrected, giving me the green light to restore the ballast and scenery.

in Bakersfield, CA. Just one minor wiring error was found and corrected, giving me the green light to restore the ballast and scenery.

Below left: The track profile issue first caused problems at the 2015 Free-mo setup in Fresno, CA. In a

desperate attempt for a quick fix, a fellow Free-mo-er and I drove around the badlands of Fresno and found

these chunks of concrete, which we used as weight to try to flatten the foam top while gluing it back onto the

frame from beneath. It didn't work. This was Glen Frazer's last setup before restoration began in 2018.

Below right: An example of a cracked latex Liquid Nails adhesive joint (red arrows for emphasis).

desperate attempt for a quick fix, a fellow Free-mo-er and I drove around the badlands of Fresno and found

these chunks of concrete, which we used as weight to try to flatten the foam top while gluing it back onto the

frame from beneath. It didn't work. This was Glen Frazer's last setup before restoration began in 2018.

Below right: An example of a cracked latex Liquid Nails adhesive joint (red arrows for emphasis).

Below: The simplest solution was to re-attach the foam tops to the

wood frames using light-weight foam blocks affixed with Gorilla glue.

Here I am cutting the blocks, which are each 1.5" x 1.5" cross-section.

This provides a significant increase in glue-able surface area to

ensure the glue joints will be very strong and stable over time.

wood frames using light-weight foam blocks affixed with Gorilla glue.

Here I am cutting the blocks, which are each 1.5" x 1.5" cross-section.

This provides a significant increase in glue-able surface area to

ensure the glue joints will be very strong and stable over time.

Below: I also removed the old NCE brand BD20 current

detectors because their sensitivity cannot be adjusted.

This caused problems for the MSS detection system

when a FRED-equipped car was on the track - the

flashing FRED intermittently draws a higher current,

which caused the signals to also flash.

detectors because their sensitivity cannot be adjusted.

This caused problems for the MSS detection system

when a FRED-equipped car was on the track - the

flashing FRED intermittently draws a higher current,

which caused the signals to also flash.

Below: In contrast, the Loading Ramp and West Switch

sections were stood upright while boards, loaded with heavy

landscaping blocks, were carefully placed on the track to

press the foam top onto the frame. The pink foam blocks

were then glued in from underneath. Oh, my aching back!

sections were stood upright while boards, loaded with heavy

landscaping blocks, were carefully placed on the track to

press the foam top onto the frame. The pink foam blocks

were then glued in from underneath. Oh, my aching back!

With the module sections mated and carefully leveled, I used a laser line level to ensure the new cork roadbed and track were

flat throughout the module. The turnouts on the Derail section (leading to the MofW siding) and on the West Switch (for the

siding track) were left in place, and used as the baseline references - the new track was installed between these two turnouts.

flat throughout the module. The turnouts on the Derail section (leading to the MofW siding) and on the West Switch (for the

siding track) were left in place, and used as the baseline references - the new track was installed between these two turnouts.

Below: I used a white level with the laser line shining on its inch

markings to determine what areas of the cork roadbed needed to

be lowered and which areas raised. In the low areas, new cork

was overlaid on top the old cork using latex Liquid Nails adhesive.

markings to determine what areas of the cork roadbed needed to

be lowered and which areas raised. In the low areas, new cork

was overlaid on top the old cork using latex Liquid Nails adhesive.

Below: Once cured, the repaired cork roadbed was shaved down

using a Sure-Form tool, with frequent checks of height against the

laser line level and side-to-side level using bubble levels.

using a Sure-Form tool, with frequent checks of height against the

laser line level and side-to-side level using bubble levels.

A consequence -- indeed, a side benefit -- of this restoration project was that most of the

wiring and electronics had to be removed to make space for the foam blocks used to stabilize

the foam tops. Because Glen Frazer was the prototype and test bed for my invention, the

Modular Signal System (MSS), the wiring methods and electronics had become dated

and were no longer fully compliant to the current V2.0 MSS standard. Once track repairs

were complete, I replaced and updated the module wiring and MSS electronics.

wiring and electronics had to be removed to make space for the foam blocks used to stabilize

the foam tops. Because Glen Frazer was the prototype and test bed for my invention, the

Modular Signal System (MSS), the wiring methods and electronics had become dated

and were no longer fully compliant to the current V2.0 MSS standard. Once track repairs

were complete, I replaced and updated the module wiring and MSS electronics.

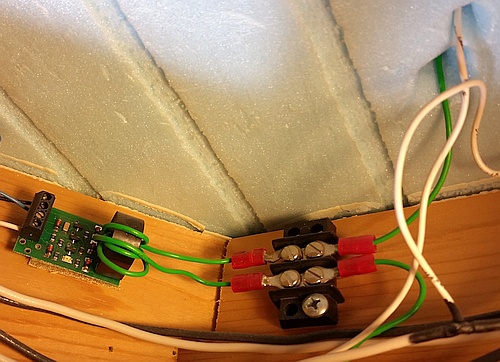

Below: Iowa Scaled Engineering (ISE) brand integrated

MSS Cascade boards (the large board) were installed in

the East Switch and West Switch sections. This product

(no longer available) incorporates the MSS Cascade, two

current detectors, one optical detector, and two signal

drivers. I also re-installed a stand-alone AutoBlock signal

driver from TracTronics (no longer available) to eventually

control the leave-siding signal. To provide 12 volts DC to

the Tortoise turnout motor, I used an old OBUB-2, which has

a 12 volt regulator powered from the MSS Accessory Bus.

MSS Cascade boards (the large board) were installed in

the East Switch and West Switch sections. This product

(no longer available) incorporates the MSS Cascade, two

current detectors, one optical detector, and two signal

drivers. I also re-installed a stand-alone AutoBlock signal

driver from TracTronics (no longer available) to eventually

control the leave-siding signal. To provide 12 volts DC to

the Tortoise turnout motor, I used an old OBUB-2, which has

a 12 volt regulator powered from the MSS Accessory Bus.

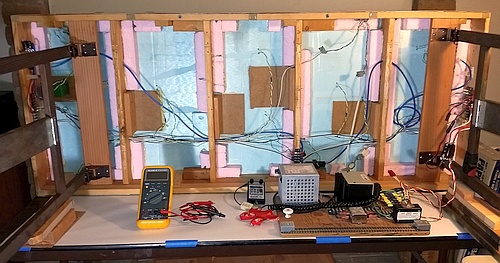

Below: New ISE current detectors (upper left) have been installed

on the Derail and Loading Ramp sections. The ISE sensor's current

sensitivity is set to detect the FRED's nominal current draw, solving

the "flashing signals" problem. The ISE boards are connected to my OBUB-3 boards (middle), which has a built-in 12 volt regulator for

powering the ISE detector and local Tortoise motors.

on the Derail and Loading Ramp sections. The ISE sensor's current

sensitivity is set to detect the FRED's nominal current draw, solving

the "flashing signals" problem. The ISE boards are connected to my OBUB-3 boards (middle), which has a built-in 12 volt regulator for

powering the ISE detector and local Tortoise motors.

During the 2019 Bakersfield setup, I discovered that Glen Frazer's original commercial phone panels used for the

LocoNet throttle jacks were no longer reliable, prompting me to rebuild the LocoNet using Digitrax UP5 panels.

LocoNet throttle jacks were no longer reliable, prompting me to rebuild the LocoNet using Digitrax UP5 panels.

Below: The Loading Ramp section with foam blocks completed.

Here, I'm testing the new ISE current detector (discussed below).

Here, I'm testing the new ISE current detector (discussed below).

Left: I replaced the old, large Optek brand optical sensors

with new smaller ISE sensors, as seen here before I added

filler tie material and ballast around it (see my method here).

Below: The cantilever signal was protected with a box to

prevent damage as I worked on the nearby optical sensor,

surrounded by blue tape.

with new smaller ISE sensors, as seen here before I added

filler tie material and ballast around it (see my method here).

Below: The cantilever signal was protected with a box to

prevent damage as I worked on the nearby optical sensor,

surrounded by blue tape.

Below: the rail was hand-painted with Floquil Roof Brown,

a slightly lighter shade than the Krylon.

a slightly lighter shade than the Krylon.

Below left: The section joints had some rather unsightly gaps and offsets in track ballast and surrounding scenery.

I used an outdoor-grade filler to solve this in conjunction with re-ballasting the track at the section joints.

I used an outdoor-grade filler to solve this in conjunction with re-ballasting the track at the section joints.

To get a very tight joint, I applied

the DAP brand filler (below) to

the end plates and belt-sanded it

down to a flat surface (right). I then

cut ABS styrene to the scenic

profile, lightly coated it with olive oil

to prevent sticking to the endplate,

and taped it in place. The modules

were then mated, leveled, and

precisely aligned. I spread scenery

dirt and ballast over the joint, filling

in around the styrene "dam", and

fixed it in place with diluted white

glue (far right). Once dry, the

modules were separated and

the styrene dam removed.

the DAP brand filler (below) to

the end plates and belt-sanded it

down to a flat surface (right). I then

cut ABS styrene to the scenic

profile, lightly coated it with olive oil

to prevent sticking to the endplate,

and taped it in place. The modules

were then mated, leveled, and

precisely aligned. I spread scenery

dirt and ballast over the joint, filling

in around the styrene "dam", and

fixed it in place with diluted white

glue (far right). Once dry, the

modules were separated and

the styrene dam removed.

Left: The finished endplate. The

white filler has filled in where the

blue foam tops had shrunk back

away from the wooden endplate

surface, providing a fresh "base"

for the new scenery material and ballast. I added small amounts of

my "fallen leaves" mixture, fuzz

grass, and puff bushes to blend

the repaired scenic dirt into the

adjacent areas. I re-ballasted the

remainder of the repaired track

in the traditional way, using small

brushes and affixed with diluted

white glue.

white filler has filled in where the

blue foam tops had shrunk back

away from the wooden endplate

surface, providing a fresh "base"

for the new scenery material and ballast. I added small amounts of

my "fallen leaves" mixture, fuzz

grass, and puff bushes to blend

the repaired scenic dirt into the

adjacent areas. I re-ballasted the

remainder of the repaired track

in the traditional way, using small

brushes and affixed with diluted

white glue.

Below: After removing the old phone panels, I glued in custom-made

laser-cut filler plates from Prawn Designs into the unsightly holes.

Basswood strips were added for extra support as needed.

laser-cut filler plates from Prawn Designs into the unsightly holes.

Basswood strips were added for extra support as needed.

Below: I filled the gaps with the outdoor-grade filler (white),

and sanded smooth. I also repaired other minor damage

to the fascias that had accumulated over the years.

and sanded smooth. I also repaired other minor damage

to the fascias that had accumulated over the years.

Below: I repainted the fascias Glidden brand "great desert"

latex, the standard fascia color for California Free-mo modules.

latex, the standard fascia color for California Free-mo modules.

Below: Once all four sections had the pink foam blocks in place,

The main track on the Derail, Ramp, and West Switch was sprayed

with water to loosen the ballast, which was then cut along the tie

edges so the bad track could be pulled up with minimal damage

to the surrounding scenery. And yes, I bumped the cantilever a few

times but managed not to destroy it, thank heavens!

The main track on the Derail, Ramp, and West Switch was sprayed

with water to loosen the ballast, which was then cut along the tie

edges so the bad track could be pulled up with minimal damage

to the surrounding scenery. And yes, I bumped the cantilever a few

times but managed not to destroy it, thank heavens!

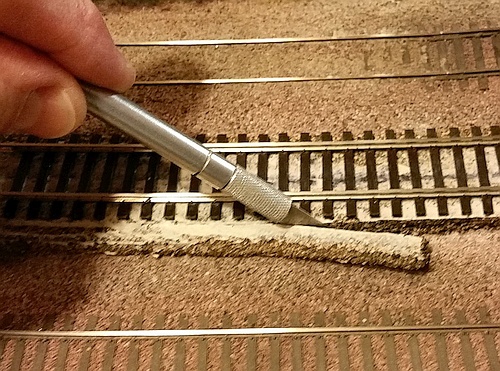

Below: The siding track had a bad dip at the Derail/Ramp

section joint, but otherwise was acceptable so I didn't tear it all

out. Rather, I used a modified hacksaw blade (background)

to undercut the track and loosen it from the underlying foam.

Custom-made styrene shims were fabricated, foreground,

and wedged under the track to raise it back to level.

section joint, but otherwise was acceptable so I didn't tear it all

out. Rather, I used a modified hacksaw blade (background)

to undercut the track and loosen it from the underlying foam.

Custom-made styrene shims were fabricated, foreground,

and wedged under the track to raise it back to level.

Below: Excess cork was trimmed away before painting track.

Below: The surrounding scenery was covered before painting the

track with Krylon ultra-flat "camouflage" brown spray paint (inset).

track with Krylon ultra-flat "camouflage" brown spray paint (inset).

Below: Digitrax UP5 throttle panels were screwed into

place, completing the restoration and updates. Glen Frazer

should be good for another 20 years of service!

place, completing the restoration and updates. Glen Frazer

should be good for another 20 years of service!

-- About

-- Contact

-- Diesels

-- Links

entire website copyright Gregg Fuhriman

created with CoffeeCup Visual Site Designer

created with CoffeeCup Visual Site Designer

-- Layouts

-- Modules

-- Signalling