|

|

Retrofitting an MSS Optical Detector from Optek to Iowa Scaled Engineering

The small Iowa Scaled Engineering (ISE) optical sensor blends into the track better

than the Optek OPB704W originally used in the Modular Signal System (MSS).

The ISE sensor is also better immune to a wide variety of

ambient lighting conditions, reducing false detections.

This is just one method to do this retrofit - also check out Gary Green's method via the Links page.

The small Iowa Scaled Engineering (ISE) optical sensor blends into the track better

than the Optek OPB704W originally used in the Modular Signal System (MSS).

The ISE sensor is also better immune to a wide variety of

ambient lighting conditions, reducing false detections.

This is just one method to do this retrofit - also check out Gary Green's method via the Links page.

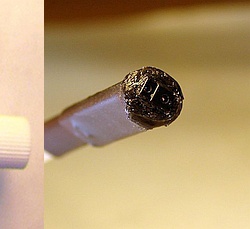

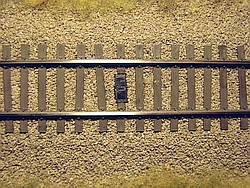

The old Optek OPB704W

installation. Note how the

sensor is slightly wider than a

track tie and is quite noticeable.

installation. Note how the

sensor is slightly wider than a

track tie and is quite noticeable.

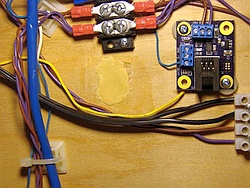

The filled hole

from trackside.

from trackside.

Left and Below: Once cured, the

Plastic Wood was (carefully)

drilled for the ISE sensor.

Plastic Wood was (carefully)

drilled for the ISE sensor.

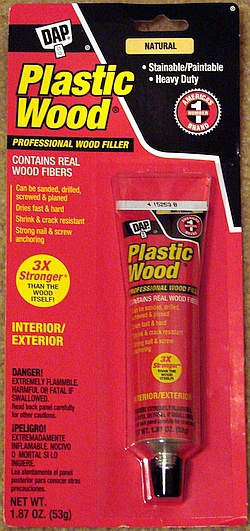

The filled hole from below.

Note the new ISE detection

board (blue) is in place.

Note the new ISE detection

board (blue) is in place.

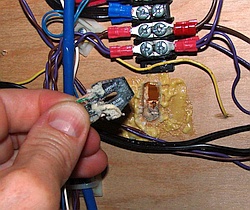

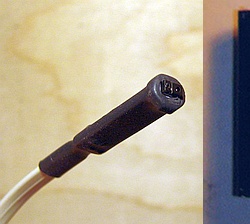

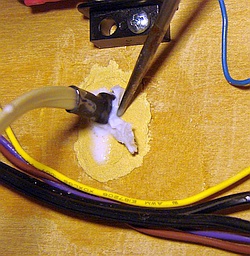

I used electrical shrink-

wrap tubing to protect

the sensor electronics.

wrap tubing to protect

the sensor electronics.

DAP Auto/Marine Sealant was used to seal the small gap between the shrink

tube edges and the sensor component. Be certain to avoid getting sealant on

the two little windows, as those are the actual infrared sensing elements.

tube edges and the sensor component. Be certain to avoid getting sealant on

the two little windows, as those are the actual infrared sensing elements.

A mash of paper towel bits and

white glue was stuffed into the

spaces around the ISE.

white glue was stuffed into the

spaces around the ISE.

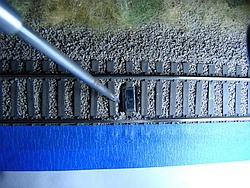

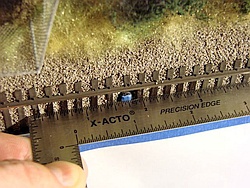

A straight-edge was used to confirm

the top of the ISE is flush with the

track ties. The blue tape protects the

sensor from being fouled with glue, etc.

the top of the ISE is flush with the

track ties. The blue tape protects the

sensor from being fouled with glue, etc.

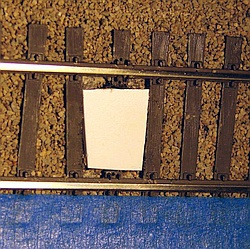

A styrene plate was placed over

the hole to prevent filler from

sploobing up onto the track.

the hole to prevent filler from

sploobing up onto the track.

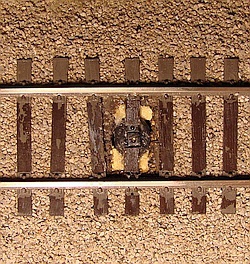

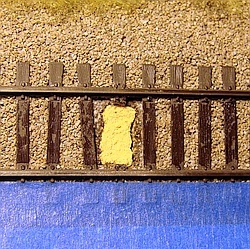

Once the ISE sensor was firmly in

place and the glue cured, small

lengths of plastic track tie were

placed on either side of the sensor to

complete the appearance of a full tie.

place and the glue cured, small

lengths of plastic track tie were

placed on either side of the sensor to

complete the appearance of a full tie.

Ballast was back-filled around the sensor, making it virtually disappear

into the track work. Be sure to cover the sensor with tape while gluing

the ballast, touching up the paint on the ties, weathering the track, etc.

into the track work. Be sure to cover the sensor with tape while gluing

the ballast, touching up the paint on the ties, weathering the track, etc.

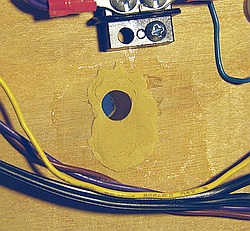

The ISE sensor temporarily set in

position. Note how much smaller

than the Optek it is, so the hole in

the track must be made smaller.

position. Note how much smaller

than the Optek it is, so the hole in

the track must be made smaller.

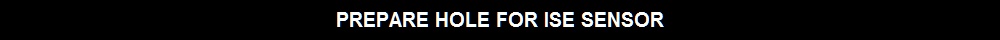

I used this material, DAP

Plastic Wood, to completely

fill the oversized hole.

Plastic Wood, to completely

fill the oversized hole.

The foam was dug out

until the Optek could be

pulled out from below.

until the Optek could be

pulled out from below.

The ballast around the Optek

was wetted to loosen the glue,

then dug out with a pick.

was wetted to loosen the glue,

then dug out with a pick.

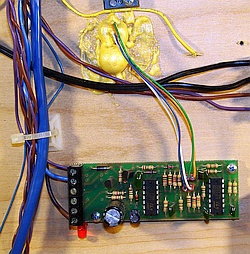

Below decks, the Optek had been

secured with expanded foam.

Note the soon-to-be-replaced

Heathcote detector board (green).

secured with expanded foam.

Note the soon-to-be-replaced

Heathcote detector board (green).

-- About

-- Contact

-- Diesels

-- Links

entire website copyright Gregg Fuhriman

created with CoffeeCup Visual Site Designer

created with CoffeeCup Visual Site Designer

-- Layouts

-- Modules

-- Signalling