|

|

ATSF DASH8-40BW 555

This is a pre-decorated Atlas product that I upgraded with added details, decals, and weathering.

I also replaced the stock LED lights to make them brighter, including the ditch lights.

This is a pre-decorated Atlas product that I upgraded with added details, decals, and weathering.

I also replaced the stock LED lights to make them brighter, including the ditch lights.

Right: Here is the prototype loco

circa 1992, in about the same

condition as I've modeled.

circa 1992, in about the same

condition as I've modeled.

Below: My model is lightly weathered to represent a unit just a year or two old. I washed diluted India ink over the

trucks and fuel / air tanks, then lightly dusted on powdered weathering chalks for the road dust effect. I brushed

diluted black paint into the various grills to give them more "depth". A spray of dull-cote ties everything together.

trucks and fuel / air tanks, then lightly dusted on powdered weathering chalks for the road dust effect. I brushed

diluted black paint into the various grills to give them more "depth". A spray of dull-cote ties everything together.

Above: Artist's oil paints were dabbed onto the exhaust stack to capture the burned,

rusty effect so common on GE locomotives.

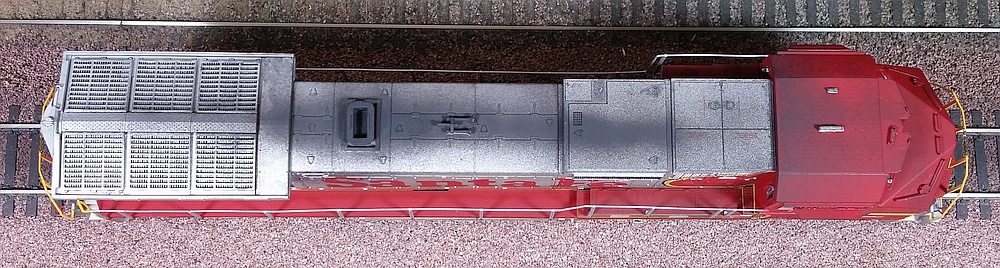

Below: The top got some diluted black airbrushed over the exhaust stack and adjacent areas.

Black powdered weathering chalk was lightly dusted over the entire top and affixed with dull-cote.

rusty effect so common on GE locomotives.

Below: The top got some diluted black airbrushed over the exhaust stack and adjacent areas.

Black powdered weathering chalk was lightly dusted over the entire top and affixed with dull-cote.

Right: I upgraded the left-side air tank piping by carving off the cast-on

plastic details (left - original part), drilling holes, and then adding

custom-formed brass wire in various gauges (right - finished upgrade).

plastic details (left - original part), drilling holes, and then adding

custom-formed brass wire in various gauges (right - finished upgrade).

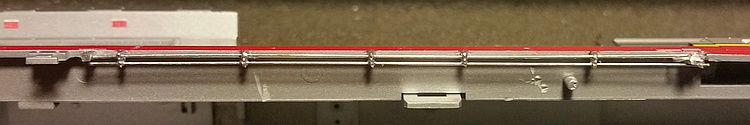

Below and Below Right: On the left side, below the sill

just behind the cab, I added new brass-wire piping to

model a detail quite visible on the prototypes. These are

tucked in behind a Details West fuel cutoff detail part.

just behind the cab, I added new brass-wire piping to

model a detail quite visible on the prototypes. These are

tucked in behind a Details West fuel cutoff detail part.

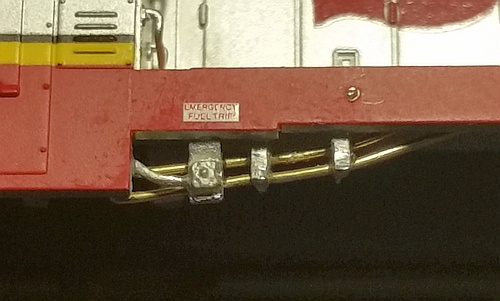

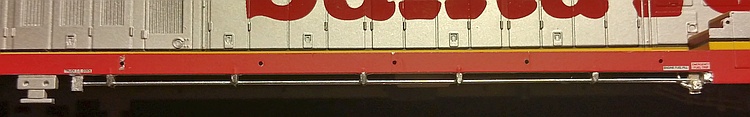

Right: On the right side below the

walkway, I used a Details West

piping kit to add another detail

that stands out on the prototypes.

The kit consists of cast metal

brackets and brass wire that

threads through them, simulating

parallel pipes/conduits. Another

Details West fuel cutoff part was

also added. These details were

brush painted Aluminum.

walkway, I used a Details West

piping kit to add another detail

that stands out on the prototypes.

The kit consists of cast metal

brackets and brass wire that

threads through them, simulating

parallel pipes/conduits. Another

Details West fuel cutoff part was

also added. These details were

brush painted Aluminum.

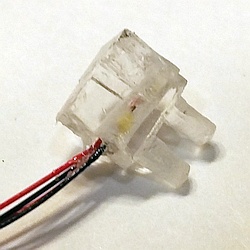

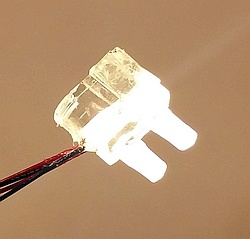

Right: I replaced the stock LED

lights with small SMT LEDs that

have wires pre-installed. I drilled

a vertical hole in the Atlas light

insert and glued in the LEDs

using a clear rubber cement.

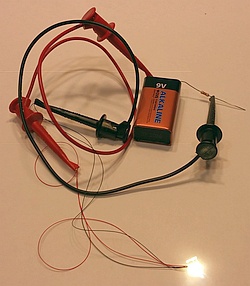

Far Right: to test LEDs during

the install process, I use a 9-volt

battery and a 1000 ohm resistor

jammed into one of the contacts.

The clip leads connect the

battery/resistor to the LED wires.

The LED-equipped light inserts

were then installed back into the

shell and secured with clear

rubber cement. Liquid electrical

tape was used to block light leaks.

lights with small SMT LEDs that

have wires pre-installed. I drilled

a vertical hole in the Atlas light

insert and glued in the LEDs

using a clear rubber cement.

Far Right: to test LEDs during

the install process, I use a 9-volt

battery and a 1000 ohm resistor

jammed into one of the contacts.

The clip leads connect the

battery/resistor to the LED wires.

The LED-equipped light inserts

were then installed back into the

shell and secured with clear

rubber cement. Liquid electrical

tape was used to block light leaks.

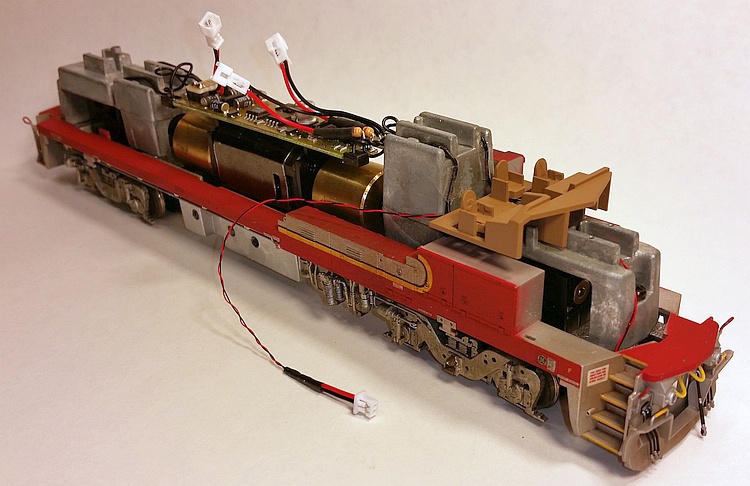

Right: Since the LEDs are now

mounted to the shell instead of

the drive, I added 2-pin micro-

connectors and current-limiting

resistors soldered to the DCC

decoder board. The mating

connectors are soldered onto

the LED leads.

This way, the shell-mounted LEDs

can be easily disconnected from

the drive-mounted decoder when

the shell needs to be removed

for repair or maintenance.

mounted to the shell instead of

the drive, I added 2-pin micro-

connectors and current-limiting

resistors soldered to the DCC

decoder board. The mating

connectors are soldered onto

the LED leads.

This way, the shell-mounted LEDs

can be easily disconnected from

the drive-mounted decoder when

the shell needs to be removed

for repair or maintenance.

-- About

-- Contact

-- Diesels

-- Links

entire website copyright Gregg Fuhriman

created with CoffeeCup Visual Site Designer

created with CoffeeCup Visual Site Designer

-- Layouts

-- Modules

-- Signalling